- Home

- Assessments

- Bioregional Assessment Program

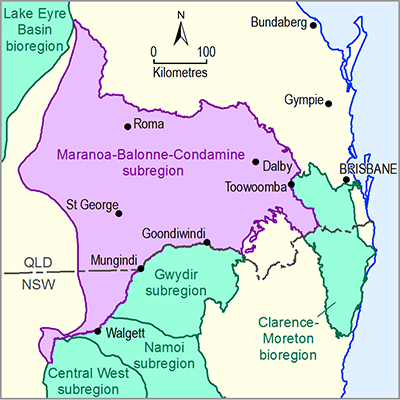

- Maranoa-Balonne-Condamine subregion

- 2.3 Conceptual modelling for the Maranoa-Balonne-Condamine subregion

- 2.3.4 Baseline and coal resource development pathway

- 2.3.4.2 Water management for the coal resource developments

- 2.3.4.2.2 Water management for coal seam gas developments

The management of co-produced water during CSG production is expected to require a number of approaches or solutions, which may vary throughout the life of the operation and across geographical areas. The Queensland Government implemented the Coal Seam Gas Water Management Policy (DEHP, 2012) to (i) articulate the government’s position on the management and use of CSG water, (ii) guide the CSG operators in co-produced water management, and (iii) ensure community understanding about the preferred approaches for co-produced water management. It aims to encourage the beneficial use of CSG co-produced water in a way that protects the environment and maximises its productive use as a valuable resource. To achieve this objective, the policy proposes the following hierarchy in the management and use of co-produced water:

- Priority 1: CSG water is used for a purpose that is beneficial to one or more of the following:

- the environment or new water users

- existing or new water-dependent industries.

- Priority 2: after feasible beneficial use options have been considered, treating and disposing CSG water in a way that firstly avoids, and then minimises and mitigates impacts on environmental values.

According to the policy, the beneficial use may include injection into depleted aquifers, substitution for an existing entitlement, supplementary water for existing irrigation schemes, new irrigation use, livestock watering, urban and industrial water supplies, coal washing and dust suppression, and release to the environment in a manner that improves local environmental values (DEHP, 2012). In determining the most appropriate beneficial use the CSG operators should consider the options in the following order:

- Consider the uses closest to the region of extraction

- Provide water to existing water users in the region of extraction

- Provide water to new water-dependent industries or users in the region of extraction.

The four major CSG operators in the Maranoa-Balonne-Condamine subregion have developed water management plans in accordance with Queensland Government’s Coal Seam Gas Water Management Policy (DEHP, 2012). RO is the preferred water treatment method by all operators, which means that beneficial use or disposal of CSG co-produced water will be preceded by RO treatment.

In all but exceptional circumstances, evaporation dams, which were common practice in CSG water management in Queensland until 2010, will not be approved as an option for managing co-produced water (DEHP, 2012). Evaporation dams will only be considered as a reasonable water disposal option during exploration activities or production testing.

Water management strategies for each baseline CSG development in the Maranoa-Balonne-Condamine subregion are summarised in Table 14.

Table 14 Water management strategies for coal seam gas operations included in the coal resource development pathway in the Maranoa-Balonne-Condamine subregion

|

Project |

Strategy |

Description |

|---|---|---|

|

Australia Pacific LNG (APLNG) Project |

Overall |

The Australia Pacific LNG (APLNG) Project EIS identified 80 water management options (APLNG, 2011a, 2011b, 2011c) that were grouped into six broad categories. Forecast peak water production volume from the combined Talinga and Condabri development areas is 48 ML/day, with peak production occurring in the first two years (APLNG, 2014). This water will be managed in an integrated manner and supplied via a water distribution pipeline along Fairymeadow Road near Miles. Treated water will be used for irrigation of commercial crops and for project activities (construction, potable water supplies and emergency supply for industrial users (APLNG, 2014). This includes a total contracted supply of 43 ML/day with a total dedicated storage of 5105 ML. |

|

Existing |

Identified options include evaporation ponds and stream discharge. A contingent release to the Condamine River is planned with the mean predicted river release volume of 3 ML/day over 24 days in the initial years (APLNG, 2014). The contingent release will occur mainly in the high rainfall years and the release will be made to flowing river conditions (i.e. releases during no flow or low-flow conditions are expected to be infrequent). In the event of an emergency situation, contingent release of treated water to the Condamine River will also be considered (APLNG, 2014). |

|

|

Industrial supply |

Supply of treated/untreated water to industry, including proposed and existing mines and power stations |

|

|

Potable water supply |

Supply of treated water to townships such as Dalby, Miles, Chinchilla and Condamine via existing distribution networks |

|

|

Agricultural supply |

Supply of treated CSG water to landholders and agriculture ventures owned and operated by APLNG in the region |

|

|

Reinjection |

Different reinjection options have been explored guided by government legislation and APLNG’s sustainability principles. Feasibility studies at the Spring Gully (outside the Maranoa-Balonne-Condamine subregion), Talinga, Condabri and Combabula gas fields have assessed the technical and economic viability of aquifer injection to offset the impacts of groundwater depressurisation in the Precipice and Hutton Sandstone (APLNG, 2012). |

|

|

Other |

Innovative technologies such as solar ponds and algae production, and large-scale options such as construction water and ocean disposal. |

|

|

Santos Gladstone LNG (GLNG) Project and Santos Gladstone LNG Gas Field Development projects |

Overall |

CSG water management options considered by Santos for the Santos GLNG Project (Santos, 2013) include beneficial uses, such as injection, irrigation, and dust suppression, and disposal options, such as release to rivers. Forecast peak production for the Santos GLNG Project life is 48 ML/day (Santos, 2013). The produced water will be managed in an integrated manner. The management options considered by Santos comprise injection, beneficial use (irrigation, dust suppression) and discharge to surface waters. |

|

Existing |

Release of treated CSG water into Dawson River is planned at the Fairview gas field. The Dawson River release scheme aims to restore part of the pre-development baseflows in the river system between the discharge location and Glebe Weir (Santos, 2013). |

|

|

Industrial supply |

Minor use for dust suppression is planned at all the fields. |

|

|

Agricultural supply |

Irrigation projects are planned for beneficial use of produced water from the Roma, Fairview and Arcadia Valley gas fields at the Mount Hope and Fairview Irrigation Projects (Santos, 2013). The Fairview gas field is outside the Maranoa-Balonne-Condamine subregion. The Mount Hope Irrigation Project is a partnership between Santos and a private landholder and will irrigate 130 ha of forage crops. The Fairview Irrigation Project will irrigate forage crops and locally adapted native tree species. |

|

|

Reinjection |

Injection into the Gubberamunda Sandstone has been found to be feasible at the Roma field, but infeasible at the Fairview site. Santos plans to inject 9–20 ML/day in the initial years of production from the Roma gas field (Santos, 2013). Reinjection from the Fairview gas field was not ecologically feasible as it would cause ephemeral catchments to become permanently flowing systems. Early results from the Arcadia Valley field (outside the Maranoa-Balonne-Condamine subregion) indicated that the aquifers are not suitable for injection (Santos, 2013). |

|

|

Queensland Curtis LNG (QCLNG) Project |

Overall |

The QCLNG Project will use the Chinchilla and Dawson Valley beneficial use schemes to manage CSG water (QGC, 2014). The Chinchilla Beneficial Use Scheme will pump water from the Southern and Central gas fields to two water treatment plants (Windibri and Kenya Water Treatment Plants) from where the treated water will be transported via a 20 km pipeline to Chinchilla Weir. Similarly, the Dawson Valley Beneficial Use Scheme will pump water from the Northern Gas Fields to the Northern Water Treatment Plant from where the treated water will be transported via a 120 km pipeline from Woleebee Creek to Glebe Weir for distribution to customers along the pipeline route. The QGC Water Management Plan envisages 97% of the treated CSG produced water to become available for beneficial use. Beneficial use of up to 185 ML/day would be achieved through two schemes proposed by QGC. |

|

Agriculture, industry, and urban water supply |

The Chinchilla Beneficial Use Scheme is authorised to supply up to 85 ML/day of treated water for irrigation and stock watering and to supplement town water supply. The Kenya Water Treatment Plant, which supplies the Chinchilla Beneficial Water Use Scheme, has a maximum treatment capacity of 112 ML/day, with 22 in-field storage ponds with capacity ranging from 104–5158 ML. The Dawson Valley Beneficial Use Scheme is authorised to supply up to 100 ML/day of water for agricultural, industry and urban water supply. The Northern Water Treatment Plant at Woleebee Creek is constructed to treat a peak flow rate of 72 ML/day, with two in-field storage ponds planned. |

|

|

Discharge to watercourse |

The beneficial use schemes will discharge treated CSG water to watercourses (i.e. Condamine River and Dawson River). |

|

|

Surat Gas Project |

Overall |

Arrow Energy seeks to maximise the beneficial use of CSG water, minimise the environmental impacts associated with CSG water use and disposal, and mitigate impacts of groundwater depressurisation. (Arrow Energy 2013b). The preferred management option for CSG water is beneficial use through substitution of existing groundwater allocations in the area for agricultural, industrial and urban use (Arrow Energy, 2013c). |

|

Agriculture |

Substituting CSG water for current irrigation extraction under existing allocations, supply to new irrigation projects and other agricultural uses, including provisions for livestock watering Irrigation trials have been conducted at Theten, outside Dalby and further beneficial use applications are being considered in the Dalby Expansion Project area. |

|

|

Industrial |

Power station cooling, coal washing, and use by Arrow Energy for construction and operational uses |

|

|

Domestic and urban |

Potential supply of treated water to towns such as Moranbah and Dalby |

|

|

Injection |

Injection feasibility studies were conducted in 2010 and deep injection trials are planned in the Dalby expansion project area. Injection trials in the Precipice Sandstone Aquifer and other shallow and deep aquifers in the Dalby Expansion Project area are planned. However, this is contingent on the finalisation of the regulatory framework for CSG water reinjection (Arrow Energy, 2013b). |

|

|

Discharge to watercourse |

This is considered as a contingency measure when beneficial use options are not feasible. |

|

|

Ocean outfall |

Disposal of CSG water to sea is also recognised as a possible option for some operational areas. |

|

|

Ironbark Project |

Overall |

CSG water management options proposed for the Ironbark Project are beneficial use, reinjection and controlled discharge (Origin Energy, 2011). The transfer of untreated CSG produced water to treatment plants at adjoining APLNG tenures for treatment prior to beneficial use or controlled discharge is also being considered. |

CSG = coal seam gas, LNG = liquefied natural gas, EIS = environmental impact statement

Product Finalisation date

- 2.3.1 Methods

- 2.3.2 Summary of key system components, processes and interactions

- 2.3.3 Ecosystems

- 2.3.4 Baseline and coal resource development pathway

- 2.3.5 Conceptual model of causal pathways

- Glossary

- Citation

- Acknowledgements

- Contributors to the Technical Programme

- About this technical product