- Home

- Assessments

- Bioregional Assessment Program

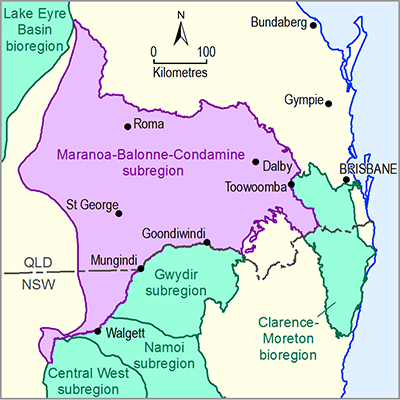

- Maranoa-Balonne-Condamine subregion

- 2.3 Conceptual modelling for the Maranoa-Balonne-Condamine subregion

- 2.3.4 Baseline and coal resource development pathway

- 2.3.4.2 Water management for the coal resource developments

- 2.3.4.2.1 Water management for coal mine developments

Different stages in the life of a mine, such as construction, production and rehabilitation, may affect water at the mine site and surrounding areas in different ways. As a result, water of varying quantity and quality is produced and managed accordingly. Water from upstream or unaffected areas is usually diverted around the mine site and released to natural watercourses. For this reason it is important to consider upstream ecological impacts. Runoff from the affected areas within a mine is typically sediment laden and contains other impurities. After a suitable treatment, this water is often used on site for various purposes such as for coal washing and dust suppression. Some of the affected waters are treated further to achieve the quality required by the relevant state environmental protection agency for release to natural watercourses. Water management strategies for all open-cut coal mines included in the CRDP are summarised in Table 13.

Table 13 Water management strategies for open-cut coal mines included in the coal resource development pathway in the Maranoa-Balonne-Condamine subregion

|

Development |

Water sources |

Water type |

Comments |

|---|---|---|---|

|

Cameby Downs Mine |

Water demand |

All |

Estimated water demand is 1500 ML/y, which is used in the coal handling and preparation plant (CHPP) and for dust suppression in haul roads and stockpiles required (Psi‑Delta, 2010). Preferred water sources, in order of preference, are mine-affected water, recycled process water, surface water runoff and make-up water from QGC’s Glen Eden Pond (Yancoal, 2015). |

|

Mine-affected water |

Other impurities |

Managed to avoid discharge to receiving water. Supplied from pit dewatering (including groundwater inflows). Collected in dams and in-pit water storage. Recycled process water recovered from the CHPP and reject streams. |

|

|

Surface water runoff from disturbed sites |

Sediment laden |

Surface water runoff captured and stored within the mine water management system is used in CHPP and for dust suppression in haul road and stockpiles. If suitable, surface water runoff is released in receiving watercourses in accordance with the conditions of the environmental authority. |

|

|

External water supply |

Clean |

Cameby Downs Mine holds a beneficial use approval (BUA) to source up to 1460 ML/y of water from QGC’s Glen Eden Pond to the Cameby Downs Mine for use in the CHPP or for dust suppression until 2029. Cameby Downs Mine also has an internal water reticulation system and sewage treatment plant. |

|

|

Surface water runoff from undisturbed sites |

Clean |

Surface water runoff is diverted around mining operation with up-catchment diversions banks, channels and flood levees. Columboola Creek is diverted around the open-cut extent of the lease area following the Australian Coal Association Research Program stream diversion design criteria (Hardie et al., 2002). Flood levees are planned with sufficient flood protection from Columboola Creek and an unnamed creek (Yancoal, 2015). |

|

|

Commodore Mine |

Water demand |

All |

Approximately 150 ML of water is required each year, which is primarily used for dust suppression at the site as the coal is not washed (Psi-Delta, 2010). No surface water or groundwater resources are accessed for mine water needs. |

|

Mine-affected water |

Other impurities |

To prevent dust emissions and spillage into the creek during conveyor transport to the nearby power station, the conveyors across creeks are fully enclosed (InterGen, 2014). |

|

|

Surface water runoff from disturbed sites |

Sediment laden |

Overland flow is collected and stored in sediment dams, which can be supplemented with recycled water. |

|

|

External water supply |

Clean |

If the overland flow is not sufficient in any one year, the mine also has access to recycled water via the nearby power station (Psi-Delta, 2010). |

|

|

Surface water runoff from undisturbed sites |

Clean |

No further information was found as of July 2015. |

|

|

Kogan Creek Mine |

Water demand |

All |

Water demand at the Kogan Creek Mine is about 180 ML/y, which is primarily used for dust suppression (Psi-Delta, 2010; WDRC, 2012) as the coal is not washed at this mine. |

|

Mine-affected water |

Other impurities |

No further information was found as of July 2015. |

|

|

Recycled process water |

Other impurities |

No further information was found as of July 2015. |

|

|

Surface water runoff from disturbed sites |

Sediment laden |

No further information was found as of July 2015. |

|

|

External water supply |

Clean |

The water supply is predominantly from groundwater bores, although overland flow is also captured (Psi-Delta, 2010). |

|

|

Surface water runoff from undisturbed sites |

Clean |

No further information was found as of July 2015. |

|

|

New Acland Coal Mine Stage 2 and Stage 3 |

Water demand |

All |

Water demand at the New Acland Coal Mine Stage 2 is 1370 ML/y, which is used for coal washing and dust suppression (Psi-Delta, 2010). Estimated water usage for the New Acland Coal Mine Stage 3 is 3300 ML/y (New Hope Group, 2014b). |

|

Mine-affected water |

Other impurities |

Water is sourced from overland flow as part of the mine’s zero discharge requirements in environmental dams that are used to capture water that collects in the mine pits and is used for dust suppression activities tailing dams. Water is collected in process water dams, which are used to supply process water to the CHPPs and aid in the management and segregation of clean and dirty water at the site. |

|

|

Surface water runoff from disturbed sites |

Sediment laden |

Surface water runoff from disturbed and mine-affected areas will be captured and treated in sediment and environmental dams before potential release off-site or use in mine-related activities (New Hope Group, 2014b). This water is used in mine-related activities, including dust suppression in haul road and stockpile. If suitable, it can be released as part of the controlled release strategy, which supports proactive management of water during periods of extended rainfall (New Hope Group, 2014b). The strategy was developed to minimise potential impacts on water quality, aquatic ecology and existing users downstream. The maximum release rate is based on the salinity of the released water and the flow in the receiving waters. Controlled releases are to be made to Lagoon Creek and the mine itself (New Hope Group, 2014b). |

|

|

External water supply |

Clean |

The Toowoomba Regional Council Wetella Wastewater Reclamation Facility (WWRF) (New Hope Group, 2014b) has a contracted supply of up to 5550 ML/y to the year 2055. The recycled water will be supplied via a 45 km pipeline that was constructed in 2009 (New Hope Group, 2014b). New Hope Group currently has a licensed groundwater capacity of up to 1412 ML/y (New Hope Group, 2014b), although water from groundwater bores is only intended to be used in emergencies (i.e. when there are problems with the recycled water supply). A small amount of additional water (up to 150 ML/y) may be sourced from the Oakey Reverse Osmosis Water treatment plant (New Hope Group, 2014b). Potable water will be sourced from aquifers via groundwater bores and treated on site by a reverse osmosis treatment plant (New Hope Group, 2014b). |

|

|

Surface water runoff from undisturbed sites |

Clean |

Surface water runoff from undisturbed areas will be diverted away and released directly into adjacent waterways (New Hope Group, 2014b). |

|

|

Wilkie Creek Mine |

Water demand |

All |

Water demand at the Wilkie Creek Mine was approximately 735 ML/y (Psi-Delta, 2010), which was used for coal washing and dust suppression (Psi-Delta, 2010). Additional water was sourced from pit dewatering and groundwater entitlements. |

|

Mine-affected water |

Other impurities |

As part of the zero discharge requirements, overland flow from the mine was captured and used to meet mine water needs. |

|

|

Surface water runoff from disturbed sites |

Sediment laden |

As part of the zero discharge requirements, overland flow from the mine was captured and used to meet mine water needs. |

|

|

External water supply |

Clean |

No further information was found as of July 2015. |

|

|

Surface water runoff from undisturbed sites |

Clean |

No further information was found as of July 2015. |

|

|

The Range |

Water demand |

All |

Water requirements of 1350 ML/y up to 2868 ML/y have been estimated for The Range coal mine (DEHP, 2013) which will predominantly be used for dust suppression and coal washing, though only about 40% of the produced run-of-mine (ROM) coal is expected to be washed (DEHP, 2013). |

|

Mine-affected water |

Other impurities |

Capture, storage and reuse of mine water (i.e. groundwater inflows and runoff water from disturbed areas, including un-rehabilitated waste rock dumps, the open-pit and mine infrastructure areas) for which four mine water dams are to be constructed progressively (staged over the life of the mine). A sediment control system, including sediment dams, to treat water diverted from rehabilitated waste rock dump areas prior to being released to the environment. |

|

|

Surface water runoff from disturbed sites |

Sediment laden |

As part of the zero discharge requirements, overland flow from the mine will be captured and used to meet mine water needs. |

|

|

External water supply |

Clean |

Water supply options considered include a branch pipeline from the proposed SunWater Nathan to Dalby pipeline; or from an off-take agreement with a coal seam gas producer (DEHP, 2013). The preferred option for the project was identified to be a connection to SunWater’s proposed Wolleebee Creek to Glebe Weir pipeline. Water collected and stored at the mine site will also be used (DEHP, 2013). External water supply will be stored in a raw water dam. |

|

|

Surface water runoff from undisturbed sites |

Clean |

A network of drains and bunds to divert clean water around disturbance areas |

Product Finalisation date

- 2.3.1 Methods

- 2.3.2 Summary of key system components, processes and interactions

- 2.3.3 Ecosystems

- 2.3.4 Baseline and coal resource development pathway

- 2.3.5 Conceptual model of causal pathways

- Glossary

- Citation

- Acknowledgements

- Contributors to the Technical Programme

- About this technical product