- Home

- Assessments

- Bioregional Assessment Program

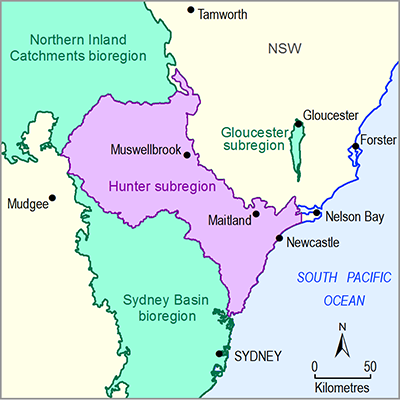

- Hunter subregion

- 1.2 Resource assessment for the Hunter subregion

- 1.2.3 Proposals and exploration

- 1.2.3.1 Coal

- 1.2.3.1.18 Mount Pleasant Mine Project

Mount Pleasant has been owned by Coal and Allied Industries Limited (Coal and Allied) since 1992. Exploration, mining studies and an EIS were completed in 1997, and development consent was originally granted in 1999. Production was initially estimated at up to 10.5 Mt/year of ROM thermal coal for international markets. The deposit has proved and probable reserves of 394 Mt of thermal coal, and over 1 Bt of identified resources (Rio Tinto, 2015). The mine project is 4 km from Muswellbrook and has four proposed pits: the North Pit, the South Pit, the Piercefield Pit and the Warkworth South Pit. The deposit trends 5 km north to south and is 6 km wide. It extends to a depth of approximately 220 m below the topographic surface (Rio Tinto, 2015). Modification 1 to the project (Mt Pleasant Coal Mine – Modification 1) was approved in September 2011 including updates to the EIS, which provided consent for mining operations to be carried on until December 2020 (NSW Department of Planning and Environment, 2015c). As at May 2015, no mining has commenced at Mt Pleasant Coal Mine, and it continues to be the subject of ongoing development studies.

The proposed Mount Pleasant Mine is an open-cut mining operation using a truck and shovel method. Around 350 employees would work in shifts to keep the mine operational 24/7 (Rio Tinto, 2015). Mining infrastructure would be constructed in the south-west corner of the project area, including a CHPP and associated coal stockpiles, an industrial area with workshops, administration and employee facilities, and a rail loading facility including a rail loop extending from the Muswellbrook–Ulan Rail line. Coarse rejects from the CHPP would be hauled by truck to the overburden emplacements. Fine rejects would be directed to a fines reject emplacement facility on the western side of the project area. Water requirements for the mine would be met through mine pit inflows, harvesting of catchment runoff and make-up water from the Hunter River. Water would primarily be used in the CHPP for dust suppression and ancillary uses such as vehicle wash-down. Water storages would be designed and sized appropriately to capture the estimated volumes of water through harvesting of catchment runoff and estimated make-up requirements. The release of water from these storages would accord with the Hunter River Salinity Trading Scheme and other regulatory requirements (Coal and Allied Operations Pty Ltd, 2011, p. 65).

The possible threatened fauna are considered to have limited impacts from activities that occur in the project area (Coal and Allied Operations Pty Ltd, 2011, p. 128). The duration and timing of impacts in the project area will occur based on the following development sequence: vegetation clearing and topsoil removal, overburden removal, coal extraction, placement of overburden in the previously mined area, final landform shaping, and replacement of topsoil and revegetation. When mining is completed the removal of vegetation for pit development will stop (Coal and Allied Operations Pty Ltd, 2011, p. 154). The mine will be rehabilitated to its final landform with reshaping and rehabilitation lagging by three years. The final mining area will be contoured and shaped. Parts of the final shape will be steep slopes and water-filled voids which will not support similar vegetation to the rest of the mine, resulting in an overall reduction in revegetated area (Coal and Allied Operations Pty Ltd, 2011, p. 125).

Product Finalisation date

- 1.2.1 Available coal and coal seam gas resources

- 1.2.2 Current activity and tenements

- 1.2.2.1 Coal

- 1.2.2.1.1 Awaba Colliery

- 1.2.2.1.2 Cumnock Mine

- 1.2.2.1.3 Mannering Colliery

- 1.2.2.1.4 Newstan

- 1.2.2.1.5 Ravensworth Underground Mine

- 1.2.2.1.6 Westside Coal Mine

- 1.2.2.1.7 Ashton Coal Mine

- 1.2.2.1.8 Austar Coal Mine

- 1.2.2.1.9 Bengalla Coal Mine

- 1.2.2.1.10 Bloomfield Coal Mine

- 1.2.2.1.11 Bulga Coal Complex

- 1.2.2.1.12 Chain Valley Colliery

- 1.2.2.1.13 Donaldson Coal Complex

- 1.2.2.1.14 Drayton Mine

- 1.2.2.1.15 Hunter Valley Operations

- 1.2.2.1.16 Integra

- 1.2.2.1.17 Liddell

- 1.2.2.1.18 Mandalong Mine

- 1.2.2.1.19 Mangoola Coal Mine

- 1.2.2.1.20 Moolarben

- 1.2.2.1.21 Mount Arthur Coal Mine Complex

- 1.2.2.1.22 Mount Owen Complex

- 1.2.2.1.23 Mount Thorley–Warkworth

- 1.2.2.1.24 Muswellbrook Coal Mine

- 1.2.2.1.25 Myuna Colliery

- 1.2.2.1.26 Ravensworth Complex

- 1.2.2.1.27 Rix's Creek Mine

- 1.2.2.1.28 Ulan

- 1.2.2.1.29 Wambo Mine Complex

- 1.2.2.1.30 West Wallsend Colliery

- 1.2.2.1.31 Wilpinjong Coal Mine

- 1.2.2.2 Coal seam gas

- References

- Datasets

- 1.2.2.1 Coal

- 1.2.3 Proposals and exploration

- 1.2.3.1 Coal

- 1.2.3.1.1 Bickham Coal Project

- 1.2.3.1.2 Bulga Coal Optimisation Project and Blakefield North Underground Mine

- 1.2.3.1.3 Bylong Coal Project

- 1.2.3.1.4 Chain Valley Modification 1

- 1.2.3.1.5 Dellworth Project

- 1.2.3.1.6 Doyles Creek

- 1.2.3.1.7 Drayton South Coal Project

- 1.2.3.1.8 Drayton Mine Extension Project

- 1.2.3.1.9 Ferndale Project

- 1.2.3.1.10 Kayuga Project

- 1.2.3.1.11 Mandalong Southern Extension

- 1.2.3.1.12 Mangoola Coal Exploration Program

- 1.2.3.1.13 Mannering Colliery Modification 2

- 1.2.3.1.14 Mitchells Flat Project

- 1.2.3.1.15 Monash Deposit

- 1.2.3.1.16 Mount Owen Continued Operations Project

- 1.2.3.1.17 Mount Penny Deposit

- 1.2.3.1.18 Mount Pleasant Mine Project

- 1.2.3.1.19 Spur Hill Project

- 1.2.3.1.20 Wallarah 2

- 1.2.3.1.21 West Muswellbrook Project

- 1.2.3.2 Coal seam gas

- References

- Datasets

- 1.2.3.1 Coal

- 1.2.4 Catalogue of potential resource developments

- Citation

- Acknowledgements

- Contributors to the Technical Programme

- About this technical product