Ulan Coal Mines Limited

Ulan Coal Mines Limited (UCML) is a joint venture between Xstrata Coal Pty Ltd (90%) and Mitsubishi Development (10%) (Umwelt, 2011c). Xstrata Coal is wholly owned by Glencore. Xstrata Coal NSW (XCN) maintains management responsibility for UCML. UCML operates the Ulan Mine Complex, in the Western Coalfields of NSW, approximately 38 km north-north-east of Mudgee (Figure 6) and 19 km north-east of Gulgong (Xstrata Coal, 2012b, p. 9). Mining in the Ulan area has taken place since the 1920s (Xstrata Coal, 2012b, p. 10) when Ulan No. 1 Colliery supplied coal to local markets for a short period and then from 1942 to 1950, supplying coal to a power station north of Ulan Village and to other local markets (Ulan Coal, 2015). The power station closed in 1969. Ulan No. 2 continued to supply coal from the underground mine to local markets and additional coal was extracted from an open-cut mine established in the 1980s. Ulan No. 3 commenced in 1986 both as underground and open pit mining (Ulan Coal, 2015).

The current lease areas are approximately 4 to 5 km north of Ulan Village although the mine’s colliery holding boundary is approximately 1.5 km north of the village. Ulan Mine Complex covers approximately 17,959 ha and is at the headwaters of the Talbragar and Goulburn river catchments (Umwelt, 2011c, p. 1; Ulan Coal, 2015). The NSW Department of Planning provided project approval (08_0184) in 2010 for coal production of up to 20 Mt/year over the next 21 years (Ulan Coal, 2015, Overview of operations). Production across the various pits at the Ulan Mine Complex equated to 7 Mt ROM coal (equating to 5.9 Mt of product coal) in 2012, 7.26 Mt ROM (6.24 Mt product coal) in 2013 and a projected 10.8 Mt ROM (10.6 Mt product coal) in 2014 (Glencore, 2014o, p. 24). The majority of coal from the Ulan Mine Complex is sold to the thermal export market and some higher-ash content coal is sold to the domestic market for power generation (Umwelt, 2011c, p. 2.1).

UCML currently hold 13 mining and exploration leases for the Ulan Mine Complex situated partially within the Central West subregion (Umwelt, 2011, p. 4.1); four of the leases cover existing activity. Ulan Mine Complex has two approved underground mining operations (Ulan No. 3, currently in operation, and Ulan West, which commenced production of longwall coal in May 2014) and an open-cut operation (Umwelt, 2011, p. 2.1). The Ulan Mine Complex is at the western limit of the Sydney Basin and the southern end of the Gunnedah Basin. At the complex, ten coal seams occur within the Permian Illawarra Coal Measures, eight above the Ulan coal seam and one below. The seams range in thickness from 0.4 to 10 m, with Ulan coal seam being the thickest (Umwelt, 2011c, p. 1.4). Apart from the Ulan Seam, all seams within the mining leases are considered to be uneconomic at present due to their high ash content (Xstrata, 2012b, p. 23). Only the lowest 3 m of the Ulan coal seam are mined due to particularly high quality and as a result, only approximately 30% of the coal requires washing (Ulan Coal, 2015). The water balance for the Ulan Mine Complex for 2012 reported that intercepted water sources including rainfall on dams and ponds was 384 ML and runoff from catchments was 1615 ML, although detail per mine/pit was not available (Xstrata Coal, 2013a). As at 31 December 2013 resources of thermal coal reported at the Ulan site were 310 Mt measured, 410 Mt indicated and 700 Mt inferred (GlencoreXstrata, 2014, p. 49).

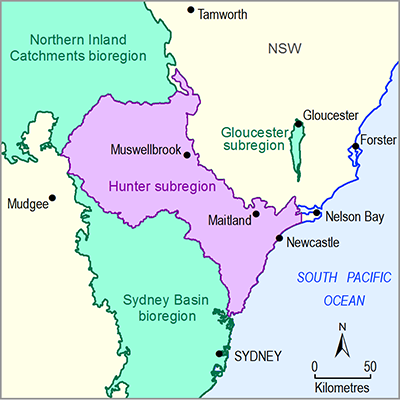

Part of Ulan No. 3 mine site is situated in the Central West subregion of the Northern Inland Catchments bioregion, including the currently mined area. However, for the purpose of this bioregional assessment product, all of the Ulan Mining Complex is discussed, even though the subregion boundary of Central West and Hunter intersects the mine complex.

Ulan No. 3 underground mine

Mining at Ulan No. 3 is performed through longwall mining methods using continuous miners and shuttle car operation (Ulan Coal, 2015). Coal is moved by conveyor to the surface where the higher-ash coal is moved by truck and conveyor to the wash plant. Coal that does not require washing is crushed and prepared for transport off site (Ulan Coal, 2015). When coal is ready for transport it is loaded at a dedicated loading facility for rail to both domestic markets and for export via the Port of Newcastle (Umwelt, 2011c, p. 2.1). The complex currently operates 24 hours a day, 7 days a week (Umwelt, 2011c, p. 2.1), with on-site facilities including mine ventilation and power supply infrastructure, fuel storage and workshops, administration buildings, tailings emplacement areas, overland and underground conveyors, stockpiles, processing and sizing stations, mine access, service boreholes, water management infrastructure, communications infrastructure, access roads and monitoring equipment (Umwelt, 2011c, p. 2.1–2.2).

Coal is of high quality with low sulfur, nitrogen and phosphorous providing good handling and combustion properties (Ulan Coal, 2015). Most coal is sold as thermal coal in the export market but some higher-ash content coal is supplied to the domestic market for power generation (Umwelt, 2011c, p. 1.6).

North 1 underground mine

The North 1 underground mine was identified in Ulan Coal Mines Continued Operations Project as a separate underground operation with longwall panels in an area that had not been previously mined, adjacent to (on the western edge of) an area that was mined in the early 1990s (Umwelt, 2011c, p. 3.1). Since that time, this is considered to be part of the Ulan No. 3 underground mine area, and not a separate entity (B Anderson (Glencore), 2014, pers. comm.).

Ulan Open Cut operation

In December 2010, open-cut mining recommenced at the Ulan Mine Complex across 239 ha adjoining the previous open-cut mining area approved for highwall mining (Umwelt, 2013, p. 2.2). Access to the Ulan Open Cut extension is via an existing road off Ulan Road approximately 1 km north of the Cope Road junction (NSW Department of Planning, 2010, p. 9). Coal from the open‑cut area is hauled by truck from the pit to a crushing facility onsite and then moved by conveyor to the CHPP (Ulan Coal, 2012, p. 57) before stockpiling and transporting off site. Coal rejects are stockpiled onsite and used for backfilling (Ulan Coal, 2012, p. 59). Approximately 158 ha of vegetation may be disturbed during construction and mining of the Ulan Open Cut extension (Ulan Coal, 2012, p. 34). Topsoil will be used for other areas undergoing rehabilitation or will be stockpiled for future rehabilitation. Minimal soil handling will be performed to reduce soil structure degradation (Ulan Coal, 2015). Overburden is blasted to fracture and aid its removal by dragline or excavator and truck to expose the Ulan Seam (Ulan Coal, 2015). The coal is crushed and then transported by overland conveyor, stockpiled and then further transported by conveyor to the CHPP, which has been upgraded to allow 20 Mt/year of coal to be processed (NSW Department of Planning, 2010, p. 9). Coal is stockpiled before being transported by rail to the Port of Newcastle or to domestic customers as required (Ulan Coal, 2015).

Ulan West underground mine

Ulan West underground longwall mine commenced production in May 2014 at longwall 1 (LW1). On 28 May 2015, mining commenced at longwall 2 (LW2) (B Anderson (Glencore), 2015, pers. comm.) and is anticipated to continue for approximately 12 months (Xstrata Coal, 2013b, p. 8). About 126 Mt of coal from the Ulan Seam is expected to be mined at Ulan West over 21 years, at depths of 80 to 225 m below surface (NSW Department of Planning, 2010, p. 9). Ulan West underground mine surface water management infrastructure includes water treatment facilities and piped services. Storage for potable water, mine wastewater, processing and fire water supply and other storage such as air, nitrogen and diesel have been developed along with a rail refuelling facility (Umwelt, 2011c, p. 2.3; Ulan Coal, 2015).

Product Finalisation date

- 1.2.1 Available coal and coal seam gas resources

- 1.2.2 Current activity and tenements

- 1.2.2.1 Coal

- 1.2.2.1.1 Awaba Colliery

- 1.2.2.1.2 Cumnock Mine

- 1.2.2.1.3 Mannering Colliery

- 1.2.2.1.4 Newstan

- 1.2.2.1.5 Ravensworth Underground Mine

- 1.2.2.1.6 Westside Coal Mine

- 1.2.2.1.7 Ashton Coal Mine

- 1.2.2.1.8 Austar Coal Mine

- 1.2.2.1.9 Bengalla Coal Mine

- 1.2.2.1.10 Bloomfield Coal Mine

- 1.2.2.1.11 Bulga Coal Complex

- 1.2.2.1.12 Chain Valley Colliery

- 1.2.2.1.13 Donaldson Coal Complex

- 1.2.2.1.14 Drayton Mine

- 1.2.2.1.15 Hunter Valley Operations

- 1.2.2.1.16 Integra

- 1.2.2.1.17 Liddell

- 1.2.2.1.18 Mandalong Mine

- 1.2.2.1.19 Mangoola Coal Mine

- 1.2.2.1.20 Moolarben

- 1.2.2.1.21 Mount Arthur Coal Mine Complex

- 1.2.2.1.22 Mount Owen Complex

- 1.2.2.1.23 Mount Thorley–Warkworth

- 1.2.2.1.24 Muswellbrook Coal Mine

- 1.2.2.1.25 Myuna Colliery

- 1.2.2.1.26 Ravensworth Complex

- 1.2.2.1.27 Rix's Creek Mine

- 1.2.2.1.28 Ulan

- 1.2.2.1.29 Wambo Mine Complex

- 1.2.2.1.30 West Wallsend Colliery

- 1.2.2.1.31 Wilpinjong Coal Mine

- 1.2.2.2 Coal seam gas

- References

- Datasets

- 1.2.2.1 Coal

- 1.2.3 Proposals and exploration

- 1.2.3.1 Coal

- 1.2.3.1.1 Bickham Coal Project

- 1.2.3.1.2 Bulga Coal Optimisation Project and Blakefield North Underground Mine

- 1.2.3.1.3 Bylong Coal Project

- 1.2.3.1.4 Chain Valley Modification 1

- 1.2.3.1.5 Dellworth Project

- 1.2.3.1.6 Doyles Creek

- 1.2.3.1.7 Drayton South Coal Project

- 1.2.3.1.8 Drayton Mine Extension Project

- 1.2.3.1.9 Ferndale Project

- 1.2.3.1.10 Kayuga Project

- 1.2.3.1.11 Mandalong Southern Extension

- 1.2.3.1.12 Mangoola Coal Exploration Program

- 1.2.3.1.13 Mannering Colliery Modification 2

- 1.2.3.1.14 Mitchells Flat Project

- 1.2.3.1.15 Monash Deposit

- 1.2.3.1.16 Mount Owen Continued Operations Project

- 1.2.3.1.17 Mount Penny Deposit

- 1.2.3.1.18 Mount Pleasant Mine Project

- 1.2.3.1.19 Spur Hill Project

- 1.2.3.1.20 Wallarah 2

- 1.2.3.1.21 West Muswellbrook Project

- 1.2.3.2 Coal seam gas

- References

- Datasets

- 1.2.3.1 Coal

- 1.2.4 Catalogue of potential resource developments

- Citation

- Acknowledgements

- Contributors to the Technical Programme

- About this technical product