Approval to operate the Sunnyside Mine, an open-cut coal mine, was granted in 2008. This allowed extraction of up to 1 Mt/year ROM coal, with an anticipated mine life of 5 to 6 years. Mining commenced in late 2008, with thermal coal extracted using conventional excavator and truck haulage.

In November 2012 the mine owner suspended all mining operations at the Sunnyside Mine indefinitely, and the mine was placed in care and maintenance. Rehabilitation and environmental management work continued at the site. As the mine was closed in the last quarter of 2012, it will be modelled as part of the baseline.

In November 2015, the development consent on the mine was extended until 2020, to allow extraction to resume if economic conditions improve.

Sunnyside lies in the Mullaley sub-basin of the Gunnedah Basin, targeting the Hoskissons Coal within the Black Jack Group. The Hoskissons Coal subcrops under primarily transported colluvial cover on the eastern flanks of Coocooboonah Creek. The depth of weathering extends approximately 30 m below surface, with the depth to the top of the Hoskissons Coal up to approximately 65 m below surface in the open-cut pit area.

The water management information presented here has been drawn from the Mining Operations Plan (MOP) Amendment C – October 2015 (Namoi Mining Pty Ltd, 2015), unless otherwise stated.

2.1.6.5.1 Mine water use

Water requirements on the mine site were expected to range between 75 and 100 ML/year (Namoi Mining Pty Ltd, 2008). No coal washing was undertaken, as the coal was transported to the Whitehaven owned Gunnedah CHPP, located off-site.

Ablutions and potable water will be trucked in from off-site. The water requirement for Sunnyside was obtained from a combination of the following sources:

- harvesting clean surface water to a maximum volume of 26.32 ML/year maximum harvestable right volume (Namoi Mining Pty Ltd, 2008)

- capture of dirty water within the site

- extraction of groundwater from one or more bores

- groundwater and surface water retained within the mine void.

Operational water requirements were preferentially sourced from dirty water runoff collected on-site, together with any surface water and groundwater which accumulated in the open-cut and pumped to designated pit dewatering dams. Any shortfall was supplemented by harvested clean water.

The water balance modelling for the mine (Namoi Mining Pty Ltd, 2008) showed that during dry years site water capture (both surface water and groundwater inflow) would be sufficient to meet operational requirements. However, during median and wet years the site water yields exceeded water storage volumes, indicating that discharge of surface water is likely to occur.

2.1.6.5.2 Surface water management

The mine site is located within an ephemeral first order stream catchment which drains north and north-west into the ephemeral Coocooboonah Creek.

Catch banks and drains were constructed to divert potentially sediment-laden waters into sediment basins. The water within those storages will be used for dust suppression and watering rehabilitated areas, if required.

Water from areas where mine plants and equipment and vehicles operate may potentially contain hydrocarbons. These areas were managed by ensuring all water was directed to oil separators and containment systems for subsequent removal.

The base of the depression remaining after rehabilitation of the final void within the open-cut area was expected to be at approximately 305 mAHD, that is, about 40 m below the current land surface, and would cover an area of approximately 18.4 ha.

2.1.6.5.3 Groundwater management

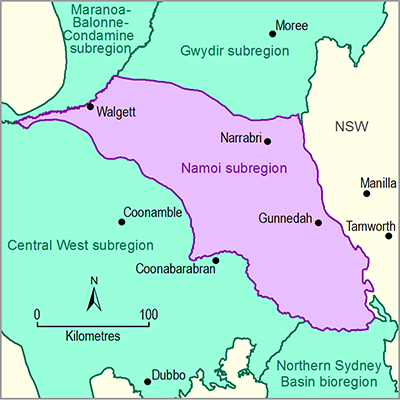

The Sunnyside Mine is located within the exposed Triassic and Permian units on the periphery of the Quaternary alluvial Upper Namoi groundwater management zone 4: Namoi Valley (Keepit Dam to Gins Leap) Groundwater Source.

The alluvium of Coocooboonah Creek to the east, and Native Cat Creek to the north, can extend to at least 50 m thick. Rock Well Creek to the west of the mine site has up to 10 m of alluvium. No registered bores extract groundwater from the alluvium within at least 3 km of the proposed mines (Namoi Mining Pty Ltd, 2015).

Groundwater within the Hoskissons Coal is unconfined where it subcrops beneath the Coocooboonah Creek alluvium, and progressively becomes more confined towards the west (down-dip) of the open-cut.

The coal resource is separated from the underground workings of the Gunnedah Coal Mine No. 5 (part of the abandoned Gunnedah Colliery) by a zone of faulting and intrusive/volcanic rocks (Namoi Mining Pty Ltd, 2015). The Gunnedah Coal Mine No. 5 underground workings are thought to be dry with a minimum volume of 1523 ML of open void space in the workings downgradient of the open-cut (Namoi Mining Pty Ltd, 2015).

The mine operators obtained the bulk of the mine water supply from pit inflows (Namoi Mining Pty Ltd, 2008). Modelled pit inflow rates are in Table 19.

Table 19 Potential pit groundwater inflows for low hydraulic conductivity scenario (without evaporation)

|

End of mining year |

Modelled pit groundwater inflows (ML/y) |

|---|---|

|

1 |

79 |

|

2 |

102 |

|

3 |

106 |

|

4 |

67 |

|

5 |

64 |

Data: Geoterra Pty Ltd (2008)

If excess inflow occurs that cannot be used on-site, or stored in the relevant storage dams, it would eventually be directed via a bore into the Gunnedah No 5 Entry underground workings. This water could then be reused as required after the appropriate licence is obtained.

Modelling was also undertaken for five years post mine closure (Geoterra Pty Ltd, 2008). The modelled groundwater level recovery scenario indicates that water levels in the final void would return to approximately 293 mAHD assuming low hydraulic conductivity or up to 302 mAHD for a higher conductivity scenario after the pit has been rehabilitated and excluding the effect of evaporation. It is noted that neither scenario had reached equilibrium during the modelling period.

Based on the short modelling period, the proponent suggests that the combined groundwater inflow and surface water capture in the final void would not generate a pit void lake, as there is insufficient inflow to raise the pit water level above the proposed basal level of 305 mAHD.

Product Finalisation date

- 2.1.1 Geography

- 2.1.2 Geology

- 2.1.3 Hydrogeology and groundwater quality

- 2.1.4 Surface water hydrology and water quality

- 2.1.5 Surface water – groundwater interactions

- 2.1.5.1 Observed data

- 2.1.5.2 Previous catchment-scale investigations on stream-aquifer interactions

- 2.1.5.3 Overview of controls on surface water – groundwater connectivity based on previous investigations in the Namoi river basin

- 2.1.5.4 Statistical analysis and interpolation

- 2.1.5.5 Gaps

- References

- Datasets

- 2.1.6 Water management for coal resource developments

- 2.1.6.1 Boggabri Coal Mine (baseline) and Boggabri Coal Expansion Project (ACRD)

- 2.1.6.2 Narrabri North Mine (baseline)

- 2.1.6.3 Narrabri South Project (ACRD)

- 2.1.6.4 Rocglen Mine (baseline)

- 2.1.6.5 Sunnyside Mine (baseline)

- 2.1.6.6 Tarrawonga Mine (baseline) and Tarrawonga Coal Expansion Project (ACRD)

- 2.1.6.7 Caroona Coal Project (ACRD)

- 2.1.6.8 Maules Creek Project (ACRD)

- 2.1.6.9 Watermark Coal Project (ACRD)

- 2.1.6.10 Vickery Coal Project (ACRD)

- 2.1.6.11 Narrabri Gas Project (ACRD)

- 2.1.6.12 Mine footprints

- References

- Datasets

- Citation

- Acknowledgements

- Currency of scientific results

- Contributors to the Technical Programme

- About this technical product