The information below is taken from the Supplementary EIS for the Kevin’s Corner Coal Project (URS, 2012).

There are seven components to the water management system:

- mine water dams (MWDs) – dams to store mine affected water (MAW)

- spoil runoff system – surface runoff from all active (un-rehabilitated) spoil and overburden dumps will be diverted and contained in a series of spoil dams and transferred to one of the MWDs

- open-cut pit dewatering system – this water is the result of either runoff or direct rainfall. A borefield will reduce groundwater seepage into the open pit to a negligible level. Water will be pumped into collection dams and then transferred to the MWDs

- process area runoff system – runoff from run-of-mine (ROM) pads and dump, train load out/product stockpile and central mine industrial area and immediate haul roads will be contained at each source and transferred to the MWDs

- CHPP and TSF process water system – water decanted from the tailings storage facility (TSF) will be reused within the coal handling and preparation plant (CHPP)/tailings pumping system. During high rainfall events, decant water may need to be transferred to MWD2 for subsequent reuse

- raw water system – supply of water for when there is insufficient quantity of water available or when the use of MAW is unsuitable

- water transfer system – the mechanical means to move water around the site.

In addition to these systems dewatering is required to allow for underground mining operations. The water will be extracted via the proposed borefield or via the underground mines. Water extracted from the underground mines as part of the mine ‘water make’ also includes the unused portion of the water demand required to sustain mining operations. All groundwater will be pumped into collection dams and then transferred to the MWDs.

2.1.6.6.1 Mine water dams

There will be two large mine water dams (MWDs) to store the MAW generated over the life of the mine. Water will be contained and collected in various smaller dams around the site and then transferred to a MWD based on proximity. The MWDs will be the source of most of the water used on site and water may be transferred between the two to meet demand or capacity requirements.

2.1.6.6.2 Spoil runoff system

All stormwater runoff originating from each spoil or overburden dump is collected by the spoil runoff system and diverted by gravity flows to one of four spoil dams. Clean runoff originating outside the spoil and overburden dumps will be passively diverted by catch drains and diversion channels to reduce the volume of water requiring containment. Water in the spoil dams will be transferred to the MWDs for reuse.

2.1.6.6.3 Open-cut pit dewatering system

It is assumed groundwater seepage into each pit will be negligible due to the operation of the borefield. Water collected by the open-cut pit dewatering system includes water entering a pit as rainfall, rainfall-runoff originating from pit ramps, temporary spoil dumps and other disturbed areas inside the pit shell. Pit dewatering inflows will be directed to a common location in the pit and pumped to a pit dewatering dam.

2.1.6.6.4 Process area runoff system

Runoff from each underground mine ROM pad will be contained in the respective adit/ROM dam and runoff from the ROM dump will be directed to the ROM dump dam. Runoff from the product stockpile pad will be collected in the train load out/product stockpile dam.

The central mine industrial area (CMIA) has too many potential sources of mine affected water (MAW) to have a separate dam for each source so all runoff from the CMIA will be treated as MAW and stored in the CMIA dam. In order to have the required capacity there will be a secondary overflow basin in the CMIA to receive overflows from the CMIA dam as required and then pump back into the CMIA dam as it is drawn down.

2.1.6.6.5 Coal handling and preparation plant and tailings storage facility process water system

The CHPP is the largest individual demand for water within the project. Process water for the CHPP and TSF will be sourced from the stored MAW except when there is insufficient water stored or additional conditioning (such as dilution) is required. In such cases raw water will be used. Tailings will be stored out-of-pit (TSF1) and in-pit (TSF2). Water from the CHPP and TSF process water system will be stored in the process water decant dam (PWDD).

2.1.6.6.6 Raw water system

Raw water will be used when there is insufficient MAW to meet project water demands and to supply water for demands that MAW is unsuitable for. The project will source raw water through an external pipeline. Raw water will be stored in the raw water dam. Raw water will be used to supply the water treatment plant to produce potable water as well as some process demands. Raw water may also be used to make-up supply for all processes that are normally supplied by MAW.

2.1.6.6.7 Water transfer system

The water transfer system is the mechanical means to move water from points of collection to points of storage and from points of storage to point of use. The water transfer system will consist of a series of pumps, pipes and storages (tanks).

Product Finalisation date

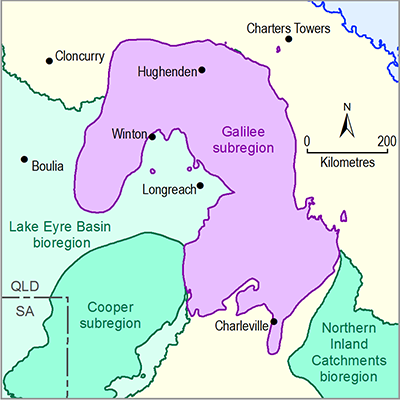

- 2.1.1 Geography

- 2.1.2 Geology

- 2.1.3 Hydrogeology and groundwater quality

- 2.1.4 Surface water hydrology and water quality

- 2.1.5 Surface water – groundwater interactions

- 2.1.6 Water management for coal resource developments

- Citation

- Acknowledgements

- Currency of scientific results

- Contributors to the Technical Programme

- About this technical product