As of February 2016, there are currently eight active coal mines and nine mines under care and maintenance (Table 5). It is unclear on the basis of available evidence when (and if) all of the mines currently in care and maintenance will resume commercial production. Hence the status shown for each operation in Table 5 may change in the future. Figure 7 shows the locations of the mines discussed in this section.

Table 5 List of mines discussed showing owner and activity status at the time of writing and coalfield in which it resides

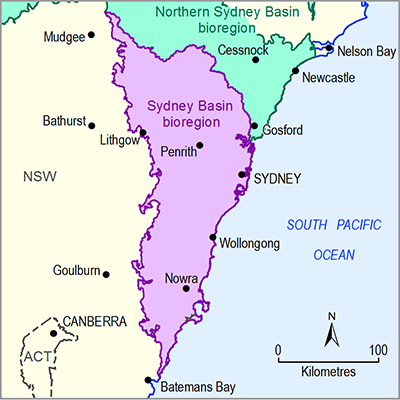

Figure 7 Mines and infrastructure in the Sydney Basin bioregion, as at 18 January 2016

Data: Bioregional Assessments Programme (Dataset 1)

1.2.2.1.1 Airly Coal Mine (Western Coalfield)

Airly is an underground mine producing thermal coal. It is operated by Centennial Airly Pty Ltd, a wholly owned subsidiary of Centennial Coal (Centennial Coal, 2014a, p. 4). Airly Mine is situated in the Western Coalfield, approximately 40 km north-north-west of Lithgow and 4 km north-east of Capertee (Centennial Coal, 2014a, p. 4). Airly Mine was first granted development consent (DA 162/91) in 1993 (GHD, 2014, p. 2) while under the ownership of Novacoal. Airly was sold to Centennial Coal on 30 December 1997 and construction commenced in March 1998 (GHD, 2014, p. 3). The first expiration of the mining lease occurred in October 2014. Centennial Coal applied for a modification to extend life of the mine for 12 months, and the Planning Assessment Commission (PAC) granted approval to continue operations until 31 October 2015 (DP&E, 2015a, p. 4). In August 2015, development consent was modified to extend the expiry date of the consent to April 2016 (PAC, 2015a, p. 1). The company has requested an extension to the mine for 20 years of additional mining followed by 5 years of decommissioning and rehabilitation (DP&E, 2015b). The extension project is discussed further in Section 1.2.3 .

Operations at Airly are approved under Mining Lease (ML) 1331, which covers about 2745 ha, as well as Authorisation A232, which covers 3054 ha (Centennial Coal, 2014a, p, 6). Although the mine was put into care and maintenance in late 2012, it re-opened in February 2014 and coal production recommenced during March 2014. The mine has been designed for a life of 25 years from 2009 at 1.8 Mt/year (Centennial Coal, 2012a; Centennial Coal, 2014a, p. 10).

Thermal coal is mined at Airly for the export market (Centennial Coal, 2012a), and is extracted from the Lithgow Coal within the Illawarra Coal Measures using bord and pillar mining methods (DP&E, 2015a). Full production capacity is 1.8 Mt/year, with remaining reserves of 33.7 Mt equivalent to 18.7 years of production (Centennial Coal, 2012a; Banpu, 2015). Production in 2015 (to October 2015) is reported as approximately 460,000 t (Centennial Coal, 2014b, p. 10).

The operation uses a continuous miner system to extract coal from underground (Centennial Coal, 2012a). On-site facilities include a coal handling and preparation plant (CHPP), as well as a rail loop and loading facility for rail transport to Port Kembla (Centennial Coal, 2012a).

1.2.2.1.2 Appin–West Cliff Mining Complex (Southern Coalfield)

The Appin–West Cliff Mining Complex has previously been known by many other names, including the Bulli Seam Operations, Bulli Seam Operations Project, Appin Coal Mine and West Cliff Colliery Complex, and Appin and West Cliff Collieries. The Appin–West Cliff Mining Complex is owned and run by South32, which in turn is owned by BHP Billiton Illawarra Coal Holdings Pty Ltd (Illawarra Coal). The mining complex is in the Southern Coalfield of the geological Sydney Basin, located 15 to 20 km west of Wollongong (Figure 7). The Appin–West Cliff Mining Complex comprises two underground mines, the Appin Mine and the West Cliff Colliery (DP&E, 2015c, p. 2).

Appin Coal Mine commenced production in 1962, working the 2 to 3 m thick Bulli Coal at a depth of about 500 m. In 1979 there was a fatal gas explosion, and gas drainage of the mine workings remains a primary concern (BHP Billiton, nd. p. 3–20). The West Cliff Colliery was granted authority to mine in 1969, and commenced activity in 1976, with longwall production starting in 1982 (BHP Billiton, nd. p. 3). The mine is approximately 480 m below surface (BHP Billiton, nd. p. 3).

As of 2011 the Appin–West Cliff Mining Complex was approved to extract up to 10.5 Mt/year of run-of-mine (ROM) coal using longwall and conventional underground mining methods until 2041 (NSW Planning and Environment, 2015, p. 2). This equated to an expected total production at the complex of 260 Mt of product coal over 30 years (PAC, 2010, p. i). The operations area for the Appin–West Cliff Mining Complex is divided into seven mining domains (PAC, 2010, p. 10), named by Illawarra Coal as North Cliff, Area 2, Area 3, West Cliff Area 5, Area 7, Area 8 and Area 9 (PAC, 2010, p. 10).

Coal is mined from the Bulli Coal and is high quality black coking coal, used for the steel making industry. Joint reserves and resources for the Appin-West Cliff Mining Complex are in Table 6.

Table 6 Resources and reserves for the Appin Coal Mine and West Cliff Colliery as at 30 June 2014

Data: South32 (2015a, p. 54)

The complex is authorised to transport up to 9.3 Mt/year ROM coal using road and rail, to Port Kembla for export, as well as to transport and emplace coal rejects at the West Cliff Emplacement (DP&E, 2015c, p. 2; South32, 2015b).

A condition of approval by the Director General to compensate for the impacts of underground mining at Appin–West Cliff Mining Complex and Dendrobium Coal Mine included a requirement to prepare and implement a biodiversity offset strategy (DP&E, 2015c p. 2). In response, a biodiversity offset has been developed to compensate for residual impacts on upland swamps and a second offset plan to compensate for the loss of water quality and loss of groundwater flows, vegetation clearing and ground disturbance in the Sydney Catchment (DP&E, 2015c, p. 2). A third proposed offset is a conservation bank (DP&E, 2015c, p. 2). South32 is currently seeking modifications to the biodiversity offset to satisfy Appin–West Cliff Mining Complex and Dendrobium Coal Mine requirements and act as a conservation bank for Illawarra Coal to draw down to compensate any subsidence impacts that may occur as mining progresses (DP&E, 2015c, p. 3).

1.2.2.1.3 Charbon Coal Mine (Western Coalfield)

Charbon Coal Mine (Charbon) ceased production in August 2015 and is currently under care and maintenance with ongoing rehabilitation of main disturbance areas (Centennial Coal, 2015a, p1, Charbon Coal Pty. Limited, 2016). The mine previously operated as both an underground and an open-cut mine (RW Corkery & Co Pty Limited, 2008, p. 5; NSW Department of Planning, 2010, p. 1). Charbon has beens a joint operation between Centennial Coal (95% share) and SK Energy Australia Pty Ltd (a wholly owned subsidiary of SK Corporation, Korea), and was acquired in 1994 from Boral (Centennial Coal, 2015b), operated by Charbon Coal Pty Ltd (NSW Department of Planning, 2010, p. 1–2). The mine is in the Western Coalfield, about 3 km south of Kandos and 50 km south-east of Mudgee (Figure 7) (NSW Department of Planning, 2010, p. 1).

Mining at Charbon commenced in 1920 and mine upgrades at the site have occurred steadily since (NSW Department of Planning, 2010, p. 2). Coal mined at the site was extracted from the Permian Illawarra Coal Measures, which includes the Charbon and Cullen Bullen subgroups. Five coal-bearing units occur within the colliery boundary, namely the Middle River Coal Member (of the Farmers Creek Formation), Moolarben Coal Member (of the State Mine Creek Formation), Irondale Coal, Lidsdale Coal and Lithgow Coal (RW Corkery & Co Pty Limited, 2008, p. 9). Remaining coal reserves reported by Centennial Coal in 2013 were approximately 1.8 Mt (proved and probable), with total resources of 4.1 Mt (Banpu, 2015).

Coal mined at Charbon was sold to the domestic and export thermal coal markets (Centennial Coal, 2015b). Locally, coal was trucked to Boral’s nearby lime and cement works and the former Wallerawang and the current Mount Piper power stations near Lithgow (NSW Department of Planning, 2010, p. 1). Coal was transported by rail to Port Kembla for the overseas market (Centennial Coal, 2015b). Full production capacity was 1.3 Mt/year ROM coal (Centennial Coal, 2015b; NSW Department of Planning, 2010, p. 2). The site consisted of five small open-cut pits and an underground mine that used a continuous miner system (NSW Department of Planning, 2010, p. 1). The pits are known as Southern Extension, Central, 8 Trunk, Western Outlier and Southern Outlier (NSW Department of Planning, 2010, p. 2).

On-site facilities included a CHPP, rail loop and rail loading facilities (Centennial Coal, 2015b). The mine was licensed for groundwater extraction of up to 30 ML/year from bores and up to 5 ML/year from the Charbon Underground Mine (Centennial Coal, 2014b, p. 7).

1.2.2.1.4 Clarence Colliery (Western Coalfield)

The Clarence Colliery Pty Ltd (Clarence) underground coal mine is a wholly owned subsidiary of Centennial Coal (itself wholly owned subsidiary of Banpu Public Company). Situated in the Western Coalfield approximately 15 km east of Lithgow, Clarence produces thermal coal for the domestic and export thermal coal markets (transported by road and rail respectively) (Centennial Coal, 2015c). The operation includes Consolidated Coal Lease (CCL) 705 and Mining Lease (ML) 1583, which are valid until 2027 (Centennial Coal, 2013, p. 13). Mining commenced in 1979 (Centennial Coal, 2013, p. 10) and the mine was acquired by Centennial Coal in 1998 (Centennial Coal, 2015c; Centennial Coal, 2013, p. 10). Centennial Coal owns 85% of the mine in a joint venture with SK Energy Australia Pty Ltd (15%) (Centennial Coal, 2015c).

Coal is extracted from seams within the Permian Illawarra Coal Measures, namely the Katoomba Coal Member (of the Farmers Creek Formation) and the Lithgow Coal using bord and pillar methods (Centennial Coal, 2013, p. 10, NSW Department of Planning, 2005, p. 1). Reserves remaining as at 2013 were estimated at 48.8 Mt (proved and probable), with total resources of 209.5 Mt (Banpu, 2015). The underground mine operates with continuous miner technology (Centennial Coal, 2015c). Clarence is authorised to extract up to 3 Mt/year of ROM coal and may transport up to 200,000 t/year of coal by road to Mount Piper Power Station (NSW Department of Planning, 2005, p. 3–4). Full production capacity of the mine is 2.5 Mt/year, although actual production rates commonly vary between 2 and 2.5 Mt/year (Centennial Coal, 2015d). For example, in 2011, the mine reported extraction of 2 Mt of coal, whereas production in 2013 was 2.4 Mt (Centennial Coal, 2015d).

Clarence operates a flexible conveyor train, which is a high capacity continuous haulage system for transporting ROM coal around the site (Centennial Coal, 2015c). Coal is transported by conveyor to the on-site CHPP and water treatment plant. Coal is then stockpiled on site prior to dispatch. Product coal is transported by rail link to Port Kembla for export market by rail via the mine’s rail loop and the main Western Railway (NSW Department of Planning, 2005, p. 1). Up to 200,000 t/year of product coal is transported to local domestic markets on public roads (NSW Department of Planning, 2005, p. 1).

Clarence Colliery is licensed to dewater the mine for safety reasons. Water is extracted via two boreholes and is transported by overland pipeline to the water treatment plant and released offsite through a licensed discharge point. Partial extraction method is used at Clarence, which reduces impact on the surrounding groundwater resources in accordance with licence requirements (Centennial Coal, 2013, p. 20). All mine water make is passed to the Clarence Colliery Water Treatment Plant (CCWTP), which has specifically been designed to remove naturally occurring manganese and iron from the raw mine water (Centennial Coal, 2013, p. 21–22).

In July 2015, a spill occurred from a coal reject stockpile at the Clarence Colliery, resulting in many tonnes of fines and coarse reject material being dispersed in the surrounding environment, including the Wollangambe River. The incident was reported to the NSW Environment Protection Authority who, in turn, inspected the site and issued a Clean-up Notice outlining the requirements (EPA, 2015). In response, the company removed the spilt reject material between the mine and river and installed 22 silt fences between the mine and the river to prevent further impact (EPA, 2015).

1.2.2.1.5 Dendrobium Coal Mine (Southern Coalfield)

Dendrobium Coal Mine (Dendrobium) is owned and operated by South32, which is owned by BHP Billiton Illawarra Coal Holdings Pty Ltd (Illawarra Coal). The mine is adjacent to Lake Cordeaux in the Southern Coalfield, approximately 15 km west of Wollongong (DP&E, 2015c, p. 1), and 80 km south-west of Sydney (Figure 7) (South32, 2015a, p. 31). Dendrobium produces coking coal that is sold to both domestic and international markets (Cardno Forbes Rigby, 2007, p. 18). The Dendrobium operations are linked to other South32 operations at nearby Appin–West Cliff Mining Complex and are closely situated. Coal rejects at Dendrobium are transported and emplaced at West Cliff Coal Wash Emplacement Area (DP&E, 2015c, p. 1). Consent to mine at Dendrobium was granted to Illawarra Coal in November 2001 (Cardno Forbes Rigby, 2007, p. 1). Although the mine has not been sold since, BHP Billiton simplified its portfolio in May 2015 by demerging a group of assets and creating an independent mining company, South32 (BHP Billiton, 2015), the current owner of the mine. The mine is at CCL 768 and the consent provided for three underground longwall areas (Area 1, Area 2 and Area 3) to be mined (Cardno Forbes Rigby, 2007, p. 1).

Coal is extracted from the Wongawilli Coal, a stratigraphic unit in the Sydney Subgroup (Cardno Forbes Rigby, 2007, p. 13). Dendrobium has development consent to extract 5.2 Mt/year of ROM coal using longwall and conventional underground methods until 2030 (DP&E, 2015c, p. 1). Mining is currently taking place in ‘Area 3B’. Resources and reserves at Dendrobium are summarised in Table 7.

Table 7 Coal resources and reserves at Dendrobium Coal Mine, as at 30 June 2014

|

Proved coal reserves (Mt) |

Probable coal reserves (Mt) |

Measured coal resources (Mt) |

Indicated coal resources (Mt) |

Inferred coal resources (Mt) |

|---|---|---|---|---|

|

21 |

24 |

86 |

91 |

118 |

Data: South32 (2015a, p. 54)

ROM coal may only be transported from the site by rail (DP&E, 2015c, p. 3). Coal is transported to the Dendrobium Coal Preparation Plant at Port Kembla Steelworks for processing. Coal rejects are transported to the West Cliff Coal Wash Emplacement Area.

Biodiversity offset programs have been developed for the Dendrobium and Appin–West Cliff Mining Complex sites as a requirement of the conditions of approval by the Director-General, to compensate for the impacts of underground mining on water quality and groundwater flow into the catchment area, upland swamps, land disturbance and vegetation clearing (DP&E, 2015c, p. 2).

1.2.2.1.6 Metropolitan Coal Mine (Southern Coalfield)

Metropolitan Coal Mine (also known as Metropolitan Collieries and Metropolitan Coal) is an underground mine, wholly owned and operated by Peabody Energy Australia Pty Ltd (Peabody Energy, 2015b). The mine is approximately 30 km north of Wollongong and adjacent to the town of Helensburgh (Figure 7) (Peabody Energy, 2015a, p. ES-1). Current approval was granted in 2009, which allows mining to take place until 2021 (Peabody Energy, 2015a, p. 7; NSW Government, 2013, p. 3) at leases CCL 703, ML 1610 and ML 1702 (Peabody Energy, 2015a, p. 1). The mine produces coking coal for domestic and export markets (Peabody Energy, 2015b).

Mining has taken place at the site since 1884 (OE&H, 2015). Longwall mining of the Bulli Seam commenced in 1995 (Helensburgh Coal Pty Ltd, 2002, p. 2). The mine has previously been known as Helensburgh Mine and Helensburgh Colliery (Helensburgh Coal Pty Ltd, 2002, p. 2; Peabody Energy, 2015a). The mine was purchased from Helensburgh Coal Pty Ltd (a wholly owned subsidiary of Peabody Pacific Pty Limited) by Peabody Energy Australia Pty Ltd and an upgrade, extension and continuation project for Metropolitan was approved in 2009 (Peabody Energy, 2015a, p. ES-1).

The mine is currently authorised to extract up to 3.2 Mt/year of ROM coal (NSW Government, 2013, p. 3) and transport a maximum of 2.8 Mt/year (NSW Government, 2013, p. 3). In 2014, Metropolitan produced 2.4 Mt of saleable coal (Peabody Energy, 2015b). The mine may operate under the current agreement until 2032 (NSW Government, 2013, p. 3). According to the OZMIN database, in 2014 Metropolitan had existing proved and probable coal reserves of about 28 Mt.

Metropolitan targets the Bulli Coal, part of the Sydney Subgroup within the Permian Illawarra Coal Measures of the Southern Coalfield (Helensburgh Coal Pty Ltd, 2002, p. 2). Mining operations use longwall technology and ROM coal is transferred by conveyor to on-site processing facilities (Peabody Energy, 2015b). From the CHPP, coal is shipped by rail to Port Kembla Coal terminal for domestic and overseas customers (Peabody Energy, 2015b).

Metropolitan pioneered the use of polyurethane resin (PUR) injections to fill localised shallow surface cracking to restore surface flows in the Sydney Drinking Water Catchment, and continues to work on this technology for further remediation purposes (Peabody Energy, 2015b). The mine is trialling underground emplacement of reject material from the CHPP, by pumping the processed reject material through pipeline into disused adits in the underground mine. Approximately 81,000 t of reject material was disposed of in this way from 2012 to 2014 (Peabody Energy 2015a, p. 329), leading to a reduction of truck movements at and from the site (Peabody Energy 2015a, p. 328).

1.2.2.1.7 Springvale Coal Mine (Western Coalfield)

Springvale is an underground longwall coal mine in the Western Coalfield of the geological Sydney Basin (Centennial Coal, 2014c, p. 5). The mine is owned by Centennial Springvale Pty Ltd (50%) and Springvale SK Kores Pty Ltd (50%), forming the Springvale unincorporated joint venture (Centennial Coal, 2014d, p. i). Mining is undertaken by Springvale Coal Pty Ltd for and on behalf of the joint venture (Centennial Coal, 2014c, p. 5; Centennial Coal, 2014d, p. i). Springvale is 10 km north-west of Lithgow and 120 km west-north-west of Sydney (Centennial Coal, 2014a, p. 5). The mine produces thermal coal for domestic and international markets (Centennial Coal, 2014a, p. 5).

Mining commenced at Springvale in 1995 (Centennial Coal, 2014c, p. 5) and operates within ML 1303, ML 1323, ML 1326, ML 1537, ML 1588, ML 1670, Mining Purposes Lease 314 and CCL 377 (DP&E, 2015d, p. 2). The previous consent for mining expired on 15 September 2015 and although an environmental impact statement was submitted to the NSW Department of Planning and Environment in April 2014 to extend the period of mining at the site, approvals for the continuation of operations were not finalised until October 2015. Operations at Springvale ceased for about two months in August 2015 due to delays in securing mining approvals, and resumed again in October 2015 following granting of the necessary approvals.

Thermal coal is produced at Springvale from the Lithgow Coal (Centennial Coal, 2014d, p. i). Remaining reserves as at end of 2013 were reported as 41.1 Mt and resources as 155.4 Mt (Banpu, 2015). The mine is currently authorised to extract up to 4.5 Mt/year ROM coal (Centennial Coal, 2014c, p. 5). In 2013 and 2014, the mine produced 2.7 Mt (Centennial Coal, 2015f) and 3.48 Mt (Centennial Coal, 2015f) respectively.

Springvale has dedicated conveyors to transport coal to the nearby Mount Piper Power Station, as well as rail loading facilities to transport coal to Port Kembla for export (Centennial Coal, 2015f). The site also has a crushing house, CHPP (Western Main) and overland conveyors to the plants (Centennial Coal, 2015f).

1.2.2.1.8 Tahmoor Coal Mine (Southern Coalfield)

Tahmoor Coal Mine (Tahmoor) is an underground longwall coal mine (Glencore, 2015a) owned and managed by Glencore plc (Glencore, 2015a). The mine is in the Southern Coalfield approximately 80 km south-west of Sydney (Figure 7) (Glencore 2014, p. 3). Operations at Tahmoor are variously referred to as Tahmoor Underground Glencore (Glencore 2014, p. 8), Tahmoor Colliery, Tahmoor Coal, Tahmoor North Underground or Tahmoor Mine. Additionally, Tahmoor South Underground is a current development project (see Section 1.2.3. 1.5). Coal produced at Tahmoor is mostly of coking quality and used for steel making. A small amount of thermal grade coal is also produced and sold for domestic power generation (AECOM, 2012, p. 1). Current mining is forecast to continue until 2019 (Tahmoor Coal, 2016).

Tahmoor was originally constructed by Clutha Development in 1975 and mining commenced in 1980 (Glencore, 2014, p. 8). The Tahmoor Washery was commissioned in 1981. In 1985 BP Coal acquired the mine from Clutha Development (Glencore, 2014, p. 8). A gas extraction facility was commissioned in 1987 at which time longwall mining commenced. BP Coal sold its interest to Conzinc Rio Tinto Australia (CRA) in 1989 (Glencore, 2014, p. 8). Austral Coal Ltd acquired Tahmoor Coal from CRA in 1997, with Centennial Coal acquiring a majority share in Austral Coal Ltd in 2005. In 2007, Xstrata Coal Pty Ltd acquired 100% shareholding in Austral Coal Ltd and with it, the ownership of Tahmoor Coal (Glencore, 2014, p. 8). In May 2013, Xstrata Coal Pty Ltd and Glencore plc merged.

Until 1987 mining at Tahmoor was undertaken using bord and pillar methods, after which longwall mining was introduced (Glencore, 2015a). The Tahmoor Mine targets the Bulli Coal, although several other coal-bearing units occur in the mine area including the Balgownie Coal Member and the Wongawilli Coal. Both of these units are relatively gassy and are major sources of carbon dioxide and methane at the mine (Glencore, 2014, p. 61). Consequently, these seams are accessed and degassed at Tahmoor for safety reasons. Some of the methane produced via this mine gas drainage is used for electricity generation by Energy Developments Ltd, with the remainder being flared (Glencore, 2014, p. 61). Operations at Tahmoor North occur within several mining leases, including ML 1376, ML 1308, ML 1539, ML 1642, and CCL 716. At Tahmoor South, the relevant consolidated coal leases are CCL 716 and CCL 747 (Glencore, 2014, p.2; AECOM, 2012, p. 1).

Tahmoor North underground workings extend north under the township of Tahmoor towards Thirlmere and Picton. Exploration and potential development activity at Tahmoor South extends south towards Bargo and east around Pheasants Nest (Glencore, 2014, p. 8). The mine currently has consent to produce up to 3 Mt /year of ROM coal (Glencore, 2015a). In 2014, the mine produced 2.4 Mt ROM coal (Glencore, 2014, p. 14). Total coal reserves (proved plus probable) at Tahmoor are estimated at 63 Mt, comprising 25 Mt proved and 38 Mt probable (Geoscience Australia, Dataset 2). Total identified coal resources (inclusive of reserves) are 65 Mt measured, 340 Mt indicated and 250 Mt inferred.

On-site facilities and infrastructure at Tahmoor include a CHPP, which can process up to 650 tonnes of coal per hour. The CHPP separates coking coal from steaming blend coal, and also removes rock and other non-coal material through screening and cyclonic processes (Glencore, 2015a).

1.2.2.1.9 Angus Place Colliery (Western Coalfield)

Angus Place Colliery is an underground coal mine owned by Centennial Springvale Pty Ltd (50%) and Springvale SK Kores Pty Ltd (50%). The Angus Place Colliery is part of the Centennial Coal asset portfolio and is operated by Centennial Angus Place on behalf of the Angus Place/Springvale joint venture (Centennial Coal, 2014c, p. 5). In March 2015 mining operations at Angus Place Colliery ceased due to the ongoing economic downturn and the mine was placed under care and maintenance. Two development crews and some equipment were redeployed to Centennial’s nearby Springvale coal mine (Centennial Coal, 2015b). As of February 2016, it is unclear when Angus Place Colliery will resume commercial operations.

Angus Place Colliery is 15 km north-west of Lithgow and 120 km west-north-west of Sydney (Centennial Coal, 2014c, p. 5). The mine produced thermal coal (Centennial Coal, 2015d) for the former power station Wallerawang and the current power station Mount Piper (Centennial Coal, 2015d). Development consent remains current and will expire at the mine in August 2024 (Centennial Coal, 2014c, p. 5).

Mining has occurred at the site for nearly 70 years (Centennial Coal, 2015d). Angus Place Colliery production commenced in 1979 as an extension of the original mine at the location, Newcorn Mine at Kerosene Vale, and was set up as a dedicated mine for producing thermal coal for local power stations. At this time it was owned by the NSW Government (Centennial Coal 2012b, p. 52), with Centennial Coal purchasing the mine in 2002 as part of the ‘Powercoal acquisition’ from NSW (Centennial Coal, 2015c).

Coal at Angus Place Colliery is extracted from the Lithgow Coal (Centennial Coal, 2012b, p. 44), which is part of the Illawarra Coal Measures. The coal measures are overlain by massive sandstone- and conglomerate-rich units. The seam is relatively horizontal, but depth of cover varies considerably at the mine site due to surface topography (Centennial Coal, 2012b, p. 6). The mine is within Mining Lease (ML) 1424 and Consolidated Coal Lease (CCL) 704 and CCL 702. Remaining coal reserves are reported as 54 Mt (Centennial Coal, 2015d).

Both longwall and continuous miner methods were most recently used to extract coal at Angus Place Colliery (Centennial Coal, 2015d). In 2014, approximately 3.4 Mt of coal was mined (Centennial Coal, 2015d). Full production capacity of the mine is 4 Mt/year. On-site facilities and infrastructure include a coal crushing plant and private haul roads to the nearby power stations (Centennial Coal, 2015d).

Water is currently pumped from the underground workings to the surface and transferred to the former Wallerawang Power Station using the Springvale–Delta Water Transfer Scheme (Centennial Coal, 2012b, p. 10). An emergency discharge point is authorised at Kangaroo Creek (a tributary of Coxs River) if water is unable to be transferred to the power station (Centennial Coal, 2012b, p.10). An extension has been sought to construct and operate facilities that will dewater boreholes and deliver water into the existing Springvale–Delta Water Transfer Scheme (Centennial Coal, 2012b).

1.2.2.1.10 Baal Bone Colliery (Western Coalfield)

Baal Bone Colliery is owned by Glencore, and is located 32 km north of Lithgow and approximately 130 km from Sydney. Baal Bone Colliery is operated by Wallerawang Collieries Pty and is both an underground and open-cut operation. The mine is situated at the location of a former mine, Ben Bullen open-cut mine, which was abandoned in 1982 (Glencore, 2015b). The development of Baal Bone Colliery was to replace the diminishing reserves as the former Wallerawang Colliery, which is situated south of Baal Bone Colliery. Final mining took place at Baal Bone Colliery in 2011. Washing and transport of coal continued until mid-2012 when the site was placed on care and maintenance (Umwelt, 2015, p. i). The mine was used until September 2012 as a training facility for Xstrata employees to provide experience and skills in underground mining (Glencore, 2015b; Glencore, 2013, p. 1). Extraction of remnant coal areas is approved until 30 December 2019 (Umwelt, 2015, p. i). In 2014 Glencore called for expressions of interest to purchase Baal Bone Colliery although the timing and nature of any further planned activity is not currently known.

1.2.2.1.11 Berrima (Medway) (Southern Coalfield)

Berrima (Medway) Colliery (also referred to as Berrima Colliery) is an underground bord and pillar coal mine in the village of Medway, 8 km west of New Berrima in the Southern Coalfield of the geological Sydney Basin (Figure 7). The mine is owned by Boral Ltd and managed by its subsidiary, Boral Cement Ltd. Mining operations were undertaken by Delta Mining (EMGA Mitchell McLennan, 2011, p. S.1; Boral, 2015a). Thermal coal produced at the mine was supplied to Boral’s neighbouring cement works. The mine entered care and maintenance in late 2013 when production was suspended due largely to unfavourable market conditions (Boral, 2014).

Mining in the area dates back to 1872 (the Rock Roof Colliery) and the Berrima Colliery commenced in 1924, operating continuously until 2013 (Boral, 2012, p. 5; Boral, 2015a; EMGA Mitchell McLennan, 2011, p. S.1). Mining targeted the Wongawilli Coal, part of the Illawarra Coal Measures, and coal was originally manually excavated (pick and shovel) using horse-drawn skips along underground rail tracks. In 1956 a continuous miner mechanism was commissioned; later three breaker line supports for roof control were installed (Boral, 2012, p. 11).

The Berrima Colliery includes the mine, a stockpiling site at a nearby historical mine (Loch Catherine) and a conveyor system (Boral, 2015a; EMGA Mitchell McLennan, 2011, p. S.1). Medway Village was originally established as an ancillary settlement for mine employees, although during the 1990s the sale of surplus land generated additional residences (Boral, 2015a). The mine had the capacity to produce up to 500,000 t/year, making it one of the smallest commercially producing coal mines in Australia (EMGA Mitchell McLennan, 2011, p. S.1). The mine operated mainly under CCL 748 (EMGA Mitchell McLennan, 2011, p. S.1). In July 2014, Boral announced it would seek approval from the NSW Government to permanently close the site (Boral, 2014, 2015b). The final closure plan seeks to permanently seal the mine entrances, construct bulkheads in the underground workings to permanently flood the underground mine, demolish and remove all surface infrastructure, remediate areas of contamination, and rehabilitate the pit top and coal storage area (Boral, 2015b, p. 30).

1.2.2.1.12 Cullen Valley Coal Mine (Western Coalfield)

Cullen Valley is an open-cut coal mine in the Western Coalfield, owned and managed by Coalpac Pty Ltd (Coalpac, 2013, p. iv). The Cullen Valley Mine is north-west of the township of Cullen Bullen, 5 km from the Mount Piper Power Station and adjacent to both the Baal Bone and Invincible collieries (Coalpac, 2015a; Coalpac, 2013, p. iv). The mine was put into care and maintenance in December 2012 and no mining activities have taken place since (Coalpac, 2013, p. iv). In October 2014, a proposal to extend the approved area for open-cut and highwall mining was rejected by the NSW Planning Assessment Commission (PAC, 2014, p. 1) and, as a result, the company has gone into liquidation.

Cullen Valley Coal Mine site contains the former mining areas of the Tyldesley and Beaumaris collieries where underground mining commenced in the late 1800s (Coalpac, 2013, p. v). Since that time a range of both open-cut and underground mining activities have taken place in the area (Coalpac, 2013, p. v). In 2000, Lithgow Coal Company commenced open-cut mining at the site (Coalpac, 2013, p. v). A mining consent modification was granted in 2004 that allowed the mine to operate for up to 21 years (until 2025) on ML 1556 and ML 1557. Following this decision, further areas of open-cut mining commenced at the site (Coalpac, 2013, p. 1). The consent also allowed for transport of up to 250,000 t of coal by year to domestic destinations other than Mount Piper Power Station (NSW Government, 2004, p. 5).

In 2007, the mine was put into care and maintenance as it was unable to renew a supply contract to the Mount Piper Power Station (Coalpac, 2013, p.2). However, commercial production resumed at the mine in 2008 when Coalpac acquired the mine from Lithgow Coal Company. Open-cut and highwall mining commenced at that time (Coalpac, 2013, p. 2). In 2010, Coalpac submitted a project application for a major expansion of both the Invincible Colliery and Cullen Valley Mine (Coalpac Consolidation Project). The proposal sought to expand open-cut and highwall mining areas into the adjacent state forest (Ben Bullen) and increase production to 2.5 Mt/year over 21 years (PAC, 2014, p. 2). The application was withdrawn by the proponent in 2013 (PAC, 2014, p. 3).

The Cullen Valley Coal Mine extracted from the Lithgow Coal of the Illawarra Coal Measures, which outcrop in some nearby areas (Coalpac, 2013, p. 11, 20). The mine had consent to produce up to 1 Mt/year, although production was typically around 700,000 t/year (Coalpac, 2015a). In 2013, when the mine went into care and maintenance, economically recoverable, accessible coal reserves were largely exhausted (PAC, 2014, p. 1).

1.2.2.1.13 Invincible Colliery (Western Coalfield)

The Invincible Colliery previously comprised both underground and open-cut coal mining operations. It is owned and managed by Coalpac Pty Ltd (Coalpac, 2015b). Invincible is located in the Western Coalfield about 160 km west of Sydney, and 25 km north-west of Lithgow, near the township of Cullen Bullen (Coalpac, 2015b; Hansen Bailey, 2014; p. i). Although it has been in care and maintenance since 2013, the colliery has had a long history of producing thermal coal for the domestic energy market.

Mining commenced at the site in the early 1900s. The mine was acquired by Coalpac in 1989 when it was a bord and pillar operation. In 2006 Coalpac started mining in an expansion area approved to produce annually up to 350,000 t of ROM coal from an open-cut mine (Coalpac, 2015b; NSW Department of Planning, 2014). Longwall underground mining was decommissioned at the site in 1988 due to an economic downturn in the coal industry (Coalpac, 2015b). Open-cut mining ceased in 2013 when the mine was put into care and maintenance by its owner. The current approval under which the mine may operate is a 2008 Ministerial Approval (PA 07-0127) (PAC, 2014, p. 1), which authorised coal extraction until 2016 in ML 1636 and ML 1638 (Hansen Bailey, 2014, p. i).

In 2010, Coalpac submitted a project application for a major expansion of the Invincible Colliery and the nearby Cullen Valley Mine (known as the Coalpac Consolidation Project). The proposal sought to expand the open-cut and highwall mining areas into the adjacent state forest and increase production to 2.5 Mt/year until 2025 (PAC, 2014, p. 2). However, this initial development proposal was refused by the PAC in June 2013. In July 2013, Coalpac submitted a revised development proposal and various addenda were subsequently made. In March 2014, Coalpac applied to modify existing approvals for the Invincible Colliery and the Cullen Valley Mine. The proposal for the Invincible Colliery included an extension of life for up to four years (to 2020), extension of the mining area for additional highwall mining and a water-sharing facility with Cullen Valley Mine (Hansen Bailey, 2014, p. i-ii, PAC, 2014, p. 2–3). However, in October 2014, the PAC again refused Coalpac’s expansion proposal (PAC, 2014). Accessible coal reserves have been exhausted and, together with the Cullen Valley Mine, Invincible remains in care and maintenance and the nature of any future operations at the site as at 28 January 2016 is currently uncertain (PAC, 2014, p. 1–2).

1.2.2.1.14 Ivanhoe Colliery (Western Coalfield)

Ivanhoe Colliery (Ivanhoe) occurs in the Western Coalfield near Lithgow, about 2.5 km south-east of Cullen Bullen and 7 km north-west of Wallerawang (Figure 7). Previous mining operations at the site, originally referred to as the Cullen Main West open-cut mine, began shortly after the Second World War, and have since been known by several names, including the Boulder Road Colliery, Ivanhoe No. 2 and Ivanhoe North. The most recent mining operations at Ivanhoe were undertaken by Centennial Coal Company Ltd (Centennial Coal), a subsidiary of the Thai-based Banpu Public Company Ltd (Banpu). This involved a small-scale mining rehabilitation project at Ivanhoe North, which focused on rehabilitating the previously abandoned (in 1953) pit workings at Cullen Main West. The approved project began in 2010 and was completed at the end of 2012, and included mining of remaining exposed coal and rehabilitation of the abandoned site (RW Corkery & Co Pty Limited, 2006, p. 1–1).

Previous operations at Ivanhoe have largely involved open-cut mining, although the Ivanhoe No. 2 underground longwall mine operated for approximately 18 months in the mid-2000s. The former Ivanhoe North open-cut mine targeted seams in the Irondale Coal, Lidsdale Coal and Lithgow Coal of the Illawarra Coal Measures (Bayly, 2012, p. 5). The Ivanhoe No 2 underground mine extracted the merged seams of the Lithgow Coal and Lidsdale Coal (Bayly, 2012, p. 5; Cordell, 2015).

The most recent open-cut truck and shovel operation ceased in 2012 (Centennial Coal, 2015e) having recovered approximately 610,000 t of coal over three years (Centennial Coal, 2015e). Coal was crushed on site and transported by truck to Mount Piper and the former Wallerawang power stations, and by rail to port for export. By the end of 2013, coal reserves were depleted and remaining measured and indicated resources were reported as 6.7 Mt (Banpu, 2015). The site was rehabilitated; remedial works included backfilling the open-cut, contouring the land surface, removing infrastructure and revegetating. Centennial have stated that an ongoing monitoring program will aim to restore the mined area to match the natural surroundings (Centennial Coal, 2015e).

1.2.2.1.15 Pine Dale Coal Mine (Western Coalfield)

Pine Dale Coal Mine (Pine Dale) is an open-cut operation owned by Enhance Place Pty Ltd, a wholly owned subsidiary of Energy Australia (Enhance Place Pty Ltd, 2014a). Pine Dale is in the Western Coalfield, approximately 17 km north-west of Lithgow and 5 km north of Wallerawang (Energy Australia, 2015). The mine is adjacent to former (now closed) coal mines, Wallerawang Colliery and Enhance Place Coal Mine, and the existing Springvale coal mine and Angus Place Colliery (NSW Department of Planning, 2011, p. 1). Coal extracted at Pine Dale was from the Lithgow Coal of the Illawarra Coal Measures. The coal was used as feedstock for the Mount Piper Power Station (NSW Department of Planning, 2011, p. 4); although since May 2014 the mine has been in care and maintenance (Energy Australia, 2015).

Pine Dale is part of the former Wallerawang Colliery and the Commonwealth Colliery. Wallerawang Colliery commenced operations underground in 1910. It closed in 1987 when underground reserves were depleted. A small, open-cut mine operated at Wallerawang Colliery from 1952 to 1954, followed 13 years later by a smaller open-cut mine, which was active from 1967 to 1969. Both of these operations were within the Wallerawang Colliery Pit Top area, partly located in the more recent Pine Dale Coal Mine and Yarraboldy Extension area (Enhance Place Pty Ltd, 2014d, p. 1). During the 1940s and 1950s the Commonwealth Colliery comprised two open-cut mines, one of which now forms a lake known as Blue Lake at the confluence of the Coxs River and Neubecks Creek (Enhance Place Pty Ltd, 2014b, p.2). The operation ceased in the 1990s and remediation included backfilling of the remaining void and surface contouring and revegetation (Enhance Place Pty Ltd, 2014d, p. 2).

The most recent phase of commercial operations at Pine Dale began in early 2006 and continued until December 2010. The most recent mining at the site occurred at the Yarraboldy (Stage 1) Extension area of Pine Dale (Energy Australia, 2015). Approval for mining to extract 350,000 t/year ROM coal (to a maximum of 800,000 t for life of approval) expired on 31 December 2014 (PAC, 2012, p. 23). However, coal reserves were exhausted to their limits prior to this, and led to the mine being put into care and maintenance in April 2014 (URS, 2014, p. iii).

Energy Australia acquired Pine Dale in 2012, just prior to the mine going into care and maintenance (Energy Australia, 2015; NSW Department of Planning, 2011, p. 1). Since that time there has been ongoing environmental monitoring of the site and some rehabilitation works. A development consent is being sought to continue mining operations (Energy Australia, 2015), although the next phase of planned mine development will require detailed planning, including public consultation and assessment by the PAC. Coal crushing and processing facilities remain on site (NSW Department of Planning, 2011) as well as loading facilities that provide for the coal to be transported to the power station via a private haul road and the local highway.

Development of a potential further expansion project (referred to as Stage 2 or Yarraboldy Stage 2 Extension project) has been referred to in the literature and is discussed in Section 1.2 .3.1.7. The timing of progression of the proposed future development at Pine Dale through the relevant government assessment processes remains uncertain.

1.2.2.1.16 Russell Vale Colliery (Southern Coalfield)

Russell Vale Colliery (Russell Vale) is an underground mine owned and operated by Wollongong Coal Limited (WCL, 2015e) (formerly Gujarat NRE Coking Coal Ltd who changed their name in February 2014). The mine is located in the Southern Coalfield, approximately 8 km north of Wollongong and 70 km south of Sydney. Russell Vale produced coking coal for export via Port Kembla Coal Terminal (PAC, 2015c, p. 5), although mining operations ceased in September 2015 and the mine is now in care and maintenance due to the ongoing economic downturn and its effects on international coal markets and difficult operating conditions (WCL, 2015b).

Operations at Russell Vale originally began in the 1880s when bord and pillar techniques were used to extract coal from the Bulli and Balgownie seams (PAC, 2015b, p. 1), with underground longwall mining commencing in the late 1960s (WCL, 2015e). The mine was previously also known as the South Bulli Colliery, first owned by the Osborne family and under the management of W. Wilson. The mine was sold around 1890 to Ebenezar Vickery and later sold to Bellambi Coal Company in 1901. In 2002 it was sold to Bellpac and subsequently sold to Gujarat NRE in 2004 (IQPC, 2015). Mining at Russell Vale targets the Wongawilli Coal and the Bulli Coal, although previously the Balgownie Coal Member of the Eckersley Formation (Sydney Subgroup) was also mined (WCL, 2015e). Bord and pillar mining was undertaken in the early years of operations, particularly in the top seam (Bulli Coal). Later the middle seam (Balgownie Coal Member) was extracted using longwall techniques from 1970 to 1982, and then later from 2001 to 2003. The mine is approved to extract up to 1 Mt/year, using continuous miner and longwall techniques, until December 2015 (PAC, 2015b, p. i).

Prior to operations ceasing in September 2015, coal production during 2015 had been intermittent, producing up to 1 Mt/year of coking coal (WCL, 2015b, 2015c). Coal is mined from the Bulli and Wongawilli seams. Total coking coal resources within the Bulli and Wongawilli coals at Russell Vale were estimated at 314.9 Mt, including 92 Mt of proved and probable reserves. An expansion project is currently (December 2015) under review by PAC and is discussed further in Section 1.2.3. 1.3. Reported reserves and resources for Russel Vale are listed in Table 8.

Table 8 Reported coal reserves and resources for WCL Russell Vale Colliery (as of 2010)

|

Proved coal reserves (Mt) |

Probable coal reserves (Mt) |

Measured coal resources (Mt) |

Indicated coal resources (Mt) |

Inferred coal resources (Mt) |

|---|---|---|---|---|

|

14.9 |

77.1 |

25.5 |

127.5 |

161.9 |

Note that resource figures are inclusive of reserves.

Data: Geoscience Australia (Dataset 2)

Infrastructure at the site includes administration offices and amenities, workshops, ROM stockpile area, conveyors, coal breaker, truck load-out facilities, water treatment and management facilities, fuel and oil storage, and electrical substation (PAC, 2015b, p. 4).

1.2.2.1.17 Wongawilli Colliery (Southern Coalfield)

WCL Wongawilli Colliery (Wongawilli Colliery) is an underground coal mine owned by Wollongong Coal Limited (WCL). Wongawilli Colliery is approximately 14 km south-west of Wollongong in the Southern Coalfield (WCL, 2015a, p. 1). It produced coking coal and was authorised to operate until 31 December 2015 (WCL, 2015a, p. 2). WCL ceased production at Wongawilli in May 2014, and the mine has since been put into care and maintenance. On 18 December 2015, WCL announced that they expect to recommence operations in early 2016 (WCL, 2015d). Wongawilli Colliery began mining in 1916 by G and C Hoskins Ltd to supply coking coal to Lithgow. Subsequently consolidated with the nearby Kemira and Nebo coal mines, it became known as the Elouera Colliery. In 2004 its then owner (BHP Billiton) proposed that the operation should cease production and become a tourist mine after its planned closure. However, in 2007, BHP Billiton sold the mine to an Indian-based company, Gujarat NRE Coking Coal Ltd (Gujarat), which continued production operations at the mine as NRE Wongawilli Colliery. In 2011 Wongawilli was approved by the NSW Government to mine within six longwall panels until December 2015. The company changed its name to Wollongong Coal Limited (WCL) in February 2014 and the mine is now known as Wongawilli Colliery (WCL, 2015f).

Coal was mined from seams within the Wongawilli Coal and Tongarra Coal (WCL, 2015f). At the site, coal was loaded onto trains for transport to the Port Kembla Coal Terminal (WCL, 2015a, p. 2). In addition to coal rail loading facilities, the site also has its own coal handling and processing plant (CHPP), water management and waste management facilities (WCL, 2015a, p. 2).

The mine is currently authorised to operate six longwall panels and to process and transport up to 2 Mt/year ROM coal (WCL, 2015a, p. 2). The OZMIN database (Geoscience Australia, Dataset 2) reports total coal reserves at Wongawilli of 33.4 Mt, comprising 16.5 Mt proved and 16.9 Mt probable reserves. The total identified resource estimated in the OZMIN database is 337 Mt (inclusive of reserves).

In late November 2015 the PAC approved WCL’s application for a 5-year extension to extract coal at Wongawilli (PAC, 2015c, p. 1). The timing for mining operations to recommence at Wongawilli currently remains uncertain. Further information about the time extension for Wongawilli is in Section 1.2.3. 1.6.